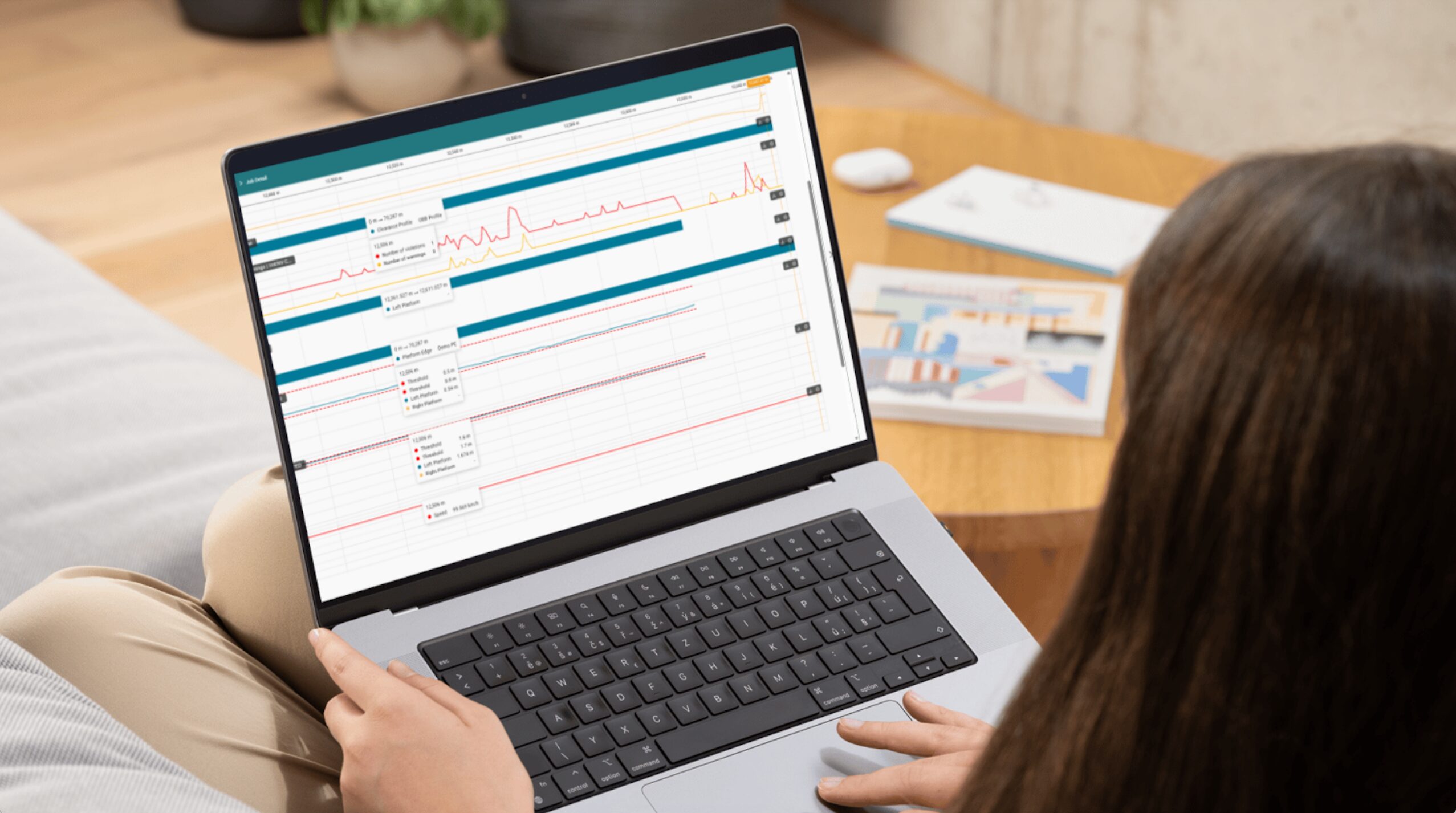

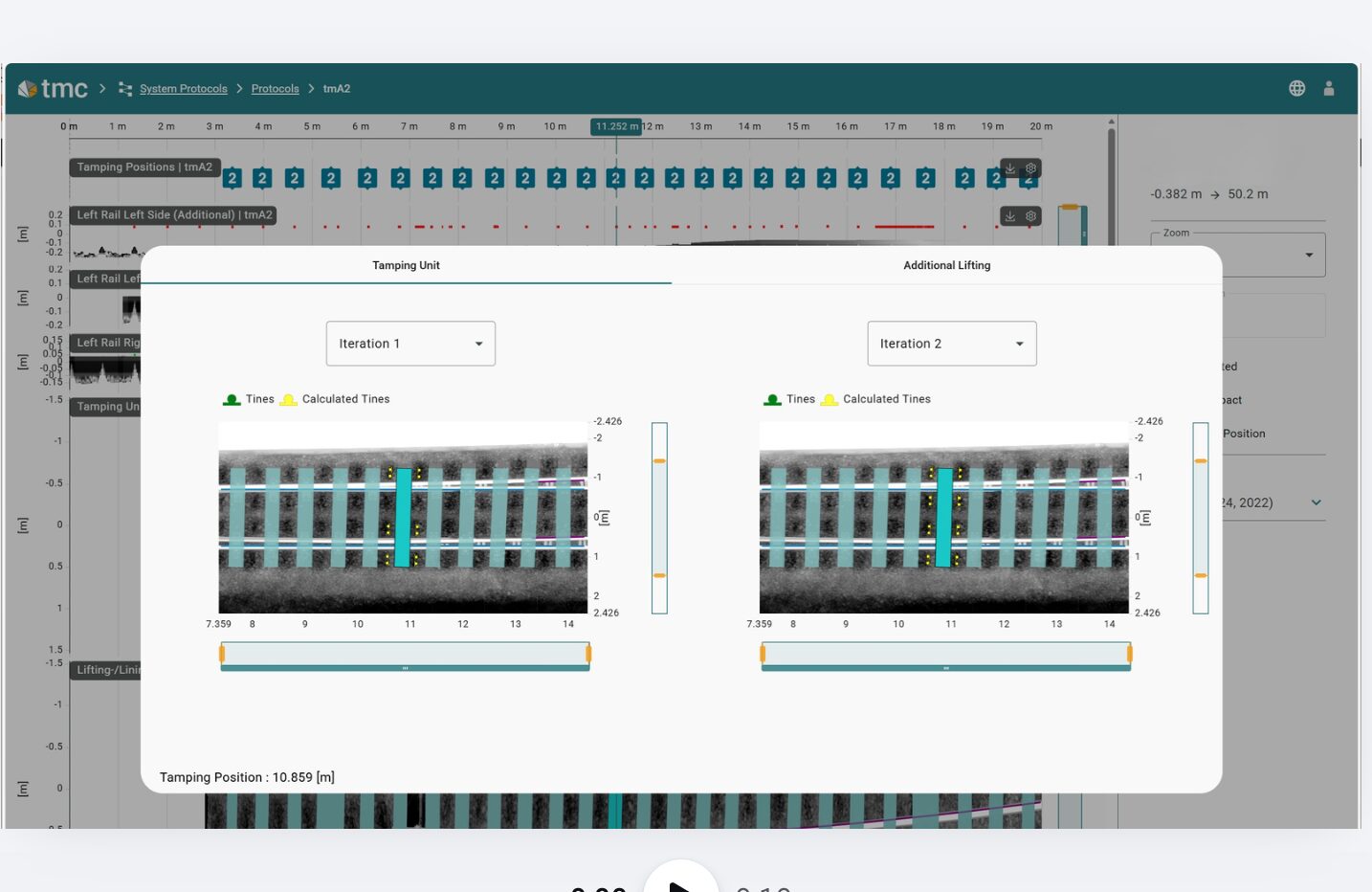

tmc recently hosted a webinar on tmENV for railway infrastructure and maintenance managers, machine manufacturers. In fact, anybody involved in the track maintenance process can benefit from this solution. Here are the top 7 reasons: tmENV transforms complex railway environments into reliable, actionable data that fits seamlessly into existing maintenance workflows. From flexible deployment to … Continued

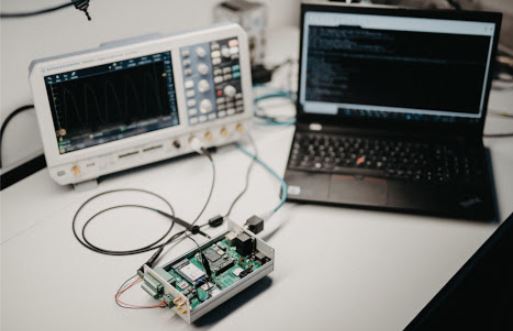

The tmMDC Machine Data Connector is our data logging edge device that’s mounted inside a track machine. It collects and uploads machine data in real time. Fleet managers around the world – from Europe and the USA to Japan and India rely on the tmMDC. It is the backbone of a networked track machine. The team around Matthias Lehner, our tmMDC product owner, has now just published a major release. Let’s look at what’s new:

tmMDC has new Linux kernel

As the tmMDC’s is the backbone for the networked track machine it also seamlessly integrates with other on-board and off-board products. That is why it’s essential that tmMDC’s operating system stays up to date. Our product team has opted for a new Linux kernel.

“New functions and Security updates are important for an Edge Device, to work with reliable and save up-to-date System on a Machine” says Matthias Lehner.

Launch of tmSYNC in Beta

As on-top feature to tmMDC we’re launching the Beta version of tmSYNC. tmSYNC synchronises the data on the machine for precise post-processing and sensor fusion of the stored data. It triggers local time synchronisation on any given machine, supporting NTP, PTP, PPS time protocols. On top of that it allows for DMI integration of the measurement wheel recording and triggering way-side impulses and calculating relative and absolute traveled distances.

With the beta version of tmSYNC we integrate the tmc products and systems of our customers to enable high precision processing on different hardware. Post-processing on side and in the cloud will be possible without any loss of precision.

More on the possibilities with tmMDC as tmSYNC becomes available with the IAF release in May 2022. Stay tuned!