Digital Track Measurement Protocols

Infrastructure Manager

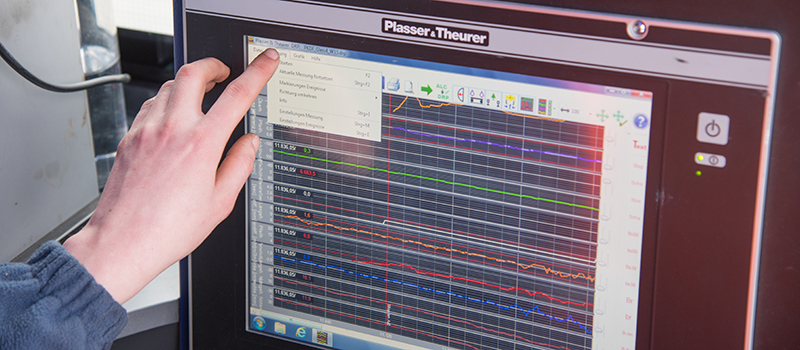

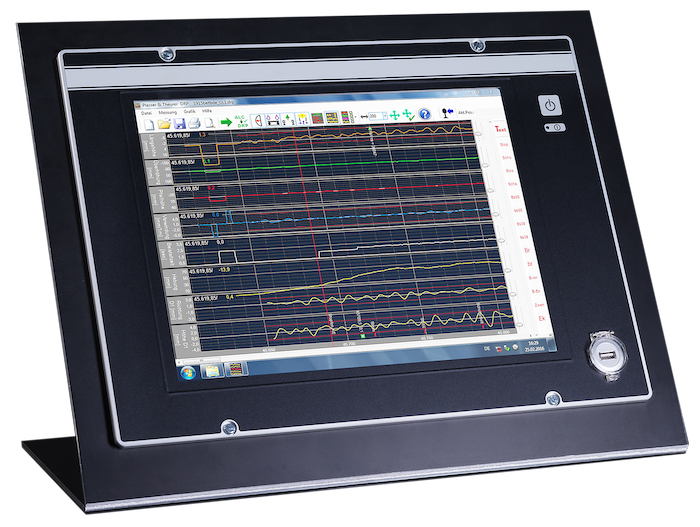

Data Recording Processor (tmDRP)

Maintenance work and acceptance processes become easier with digital, graphic track measurement protocols.

With the electronic measuring recorder from tmc, recording, evaluating and displaying various track parameters is easy. Reports can be defined flexibly and specifically tailored to railway needs.

Product Details

The electronic measuring recorder or data recording processor (tmDRP) is used to verify the completed work of a tamping machine. It graphically displays the recorded track measurement data. This means that errors can be spotted quickly and easily. Also, tolerance levels can be defined and adhered to. This makes the acceptance process of a project more effective and smoother for both infrastructure operators and contractors. The digitized processing of the measured track parameters offers many new options for further track evaluation. The tmDRP can be used worldwide and is railway certified.

Your Benefits

- Measurement accuracy according to the EN 13848 series of standards

- High quality, digital track measurement protocols according to European norm EN 13231-1 – Railway applications – Track – Acceptance of work

- Flexible, rail-specific evaluation of track parameters

- Benchmarking and transparency in track measurement

- 20 languages available as well as railway line and country specific settings

- Automated reports of non-compliance with tolerance levels

- Avoid sources of error

- Easy project acceptance

Testimonials