Transparent Track Machines

Fleet & Tool Owner

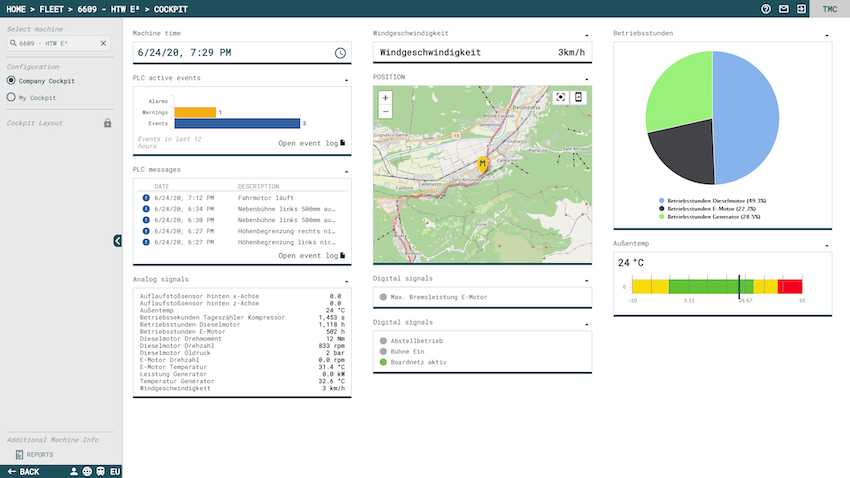

Machine Condition Observer (tmMCO)

Make the most of your machine by using its collected data to optimize maintenance and your fleet.

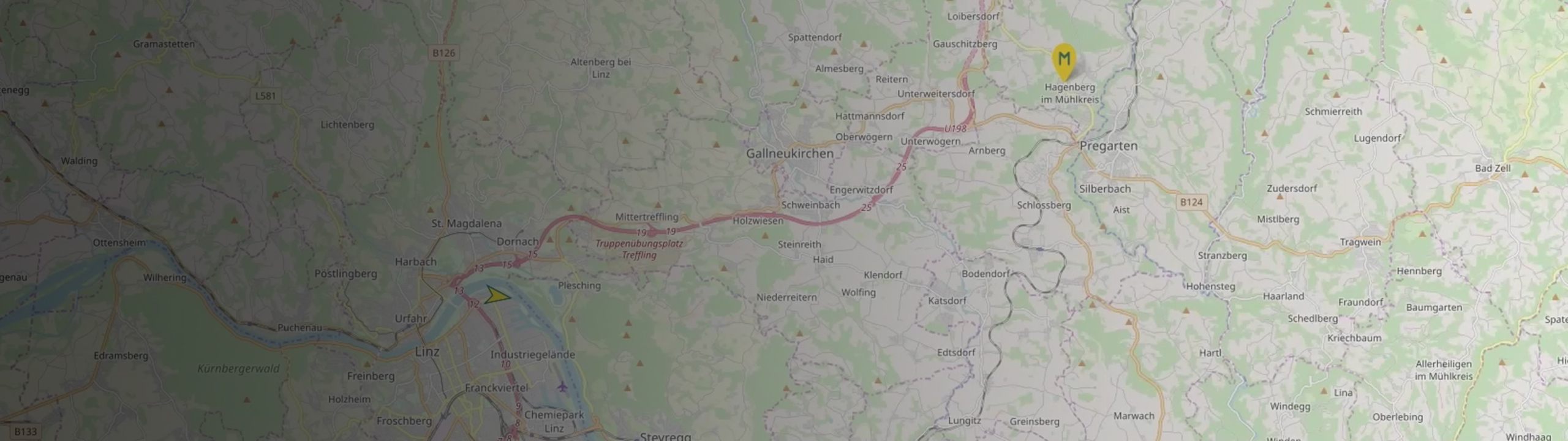

The Machine Condition Observer is your key to answer questions about the status and location of your machine in detail and in real time from anywhere. The long-term statistics it provides are particularly interesting to machine owners, because they are an important step towards the predictive maintenance of track machines. Predictive maintenance lowers maintenance costs and allows for a prolonged machine lifespan. And since track machines are quite large, but still undetectable at times on long sidings or shunting stations: this will no longer happen to you. The tmMCO shows the exact location of the machine on Google Maps. You can also use Google Maps to navigate yourself or your team to the machine.

Product Details

The Machine Condition Observer (tmMCO) is a web-based platform for the vendor-independent monitoring of your track machine or fleet. The tmMCO seamlessly integrates the data collected by the Machine Data Connector and displays your machine digitally, on any screen. Thanks to the user-friendly interface, you can see and evaluate every detail of your machine or fleet on your laptop, tablet or desktop and thus monitor utilization, operating times and many other useful parameters. All you need is an internet connection. We already process more than 1 million data points per day from over 300 machines on four continents.

Your Benefits

- Machines and customer-related reports

- Overview of operating times & utilization of the fleet

- Long-term statistics for predictive maintenance

- Early detection of problems: delays, temperature, location, etc.

- Locate your machines in real-time