Every time a new track machine or rail-bound vehicle is constructed, it must meet the specific Clearance Profile requirements of the country in which it will operate. To simplify this process, tmc introduced the Machine Clearance Measurement System, short tmMCM.

Digital tamping assistant makes a big impact in short maintenance windows.

Infrabel is responsible for the maintenance and modernisation of Belgium’s railway infrastructure. Its 3,602-kilometer network is one of the densest in the world and runs at high capacity, which means it has to withstand high levels of stress. This is why Infrabel has invested in the renewal of track machines that are digitally powered with tmA² – our Tamping Assistant. Installation and commissioning on four Infrabel track maintenance machines has now been completed.

“Digitalization is a powerful tool for railway infrastructure maintenance that we are starting to employ. Using the digital tamping assistant on our track maintenance machines to make tamping even more efficient and accurate aligns very well with our mission to provide a safe, modern and high-quality rail network” says Annelies Stevens, Manager Switches at Infrabel.

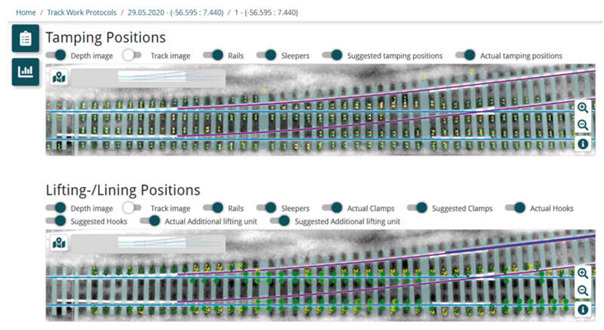

The tmc Tamping Assistant (tmA²) is an AI-based assistance system that scans and assesses the railway track. It then provides recommendations for action. “With each use tmA² works even better and more autonomous. Every tamping experience of different level-crossings at Infrabel further increases its efficiency and performance” says Karl Kernstock, CTO at tmc. Direct feedback to the machine operator during the tamping process makes training new staff easier and leads to consistent, high-quality tamping results.

Equally important, tmA² automatically protocols maintenance work done, which is a first step towards consistent, traceable and optimized maintenance. In short, it makes all aspects of tamping easier. If you order a new tamping machine, get it ready for the future with the digital tamping assistant. To find out more about the digital Tamping Assistant visit our tmA² product page or contact us.