Digital Track Measurement

Infrastructure Manager

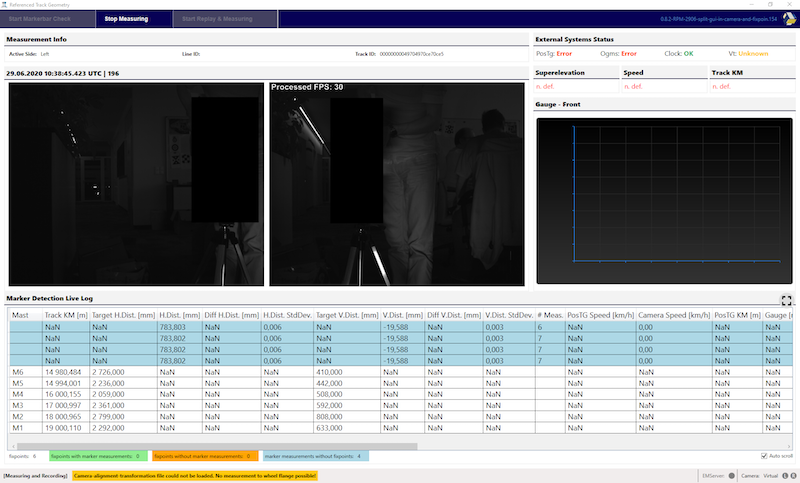

Referenced Track Geometry (tmRTG)

Tracks can now be measured safely and 16 times faster with the same level of precision.

Infrastructure operators no longer have to close entire railway sections and maintenance staff no longer need to work trackside for accurate track measurement. Referenced Track Geometry (tmRTG) allows you to measure a rail track section of 100km in 75 minutes. This is possible because you can now operate the machine that measures the tracks at speeds of up to 80 km/h which was previously only possible at 5 km/h. The new, digital way of track measurement is resource efficient and much safer for maintenance staff.

Product Details

The days of conventional track measurement using prisms and tachymeter stations are numbered. The tmRTG rings in the digital age of track measurement. What is needed to switch to digital rail track measuring? First off, markers. They are attached only once to the track and are not removed. Then sensors and hardware are attached to the rail track machine. In combination with our web-based platform, the track measurement can then be carried out quickly, precisely and resource efficient. To ensure the safety and longevity of railway infrastructure the absolute track geometry can be precisely determined with tmRTG, the newest solution in our portfolio. We are currently working on the first three projects in Europe.

Your Benefits

- Fastest, safest type of track measurement

- Highly precise

- No track closures

- Resource efficiency – less time and cost

- Parameters required for track maintenance are directly transferred to the track machine